Tier 4 Simple Guide for Operators

Q: What is Tier 4 ? (Tier 4 Interim and Tier 4 Final refer to the emission levels of an engine. Also known as EU Stage IV)

A: ALL engine manufacturers must reduce exhaust emissions and the different levels of reductions are know as “Tier” and the number also refers to the level set.

Q: How do engine manufacturers achieve this ?

A: To meet regulations there are 4 main ways of achieving this

- Using an oxidation catalyst (DOC)

- Using diesel particle filter (DPF)

- Using ad blue (SCR)

- Using regen system (EGR)

Oxidation Catalyst (DOC)

Simple system – uses chemical reactions to remove harmful gases (limited to engine size)

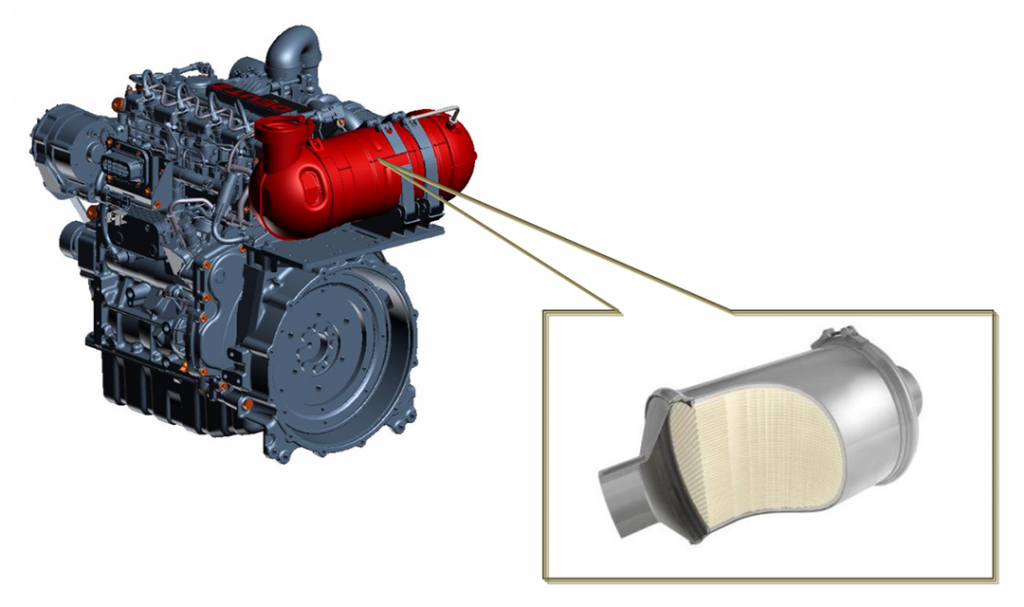

2. Diesel Particle Filter (DPF)

Using a diesel particle filter – this depends on the engine size and the exhaust gasses produced, basically it’s an exhaust filter that catches soot and turns it to ash. These exhaust filters become blocked up over a period of time and as part of routine maintenance need removing and cleaning (intervention depends on machine operation but estimate around 5000-6000 machine hours).

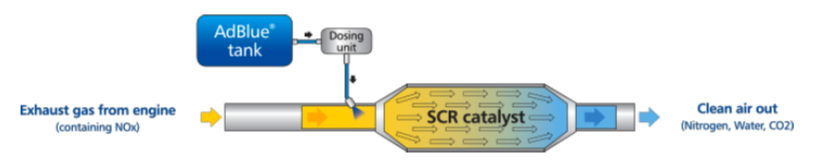

3. Ad Blue (SCR)

What is Ad Blue ?

Ad Blue is a mixture of around 33% urea and 67% water, which is injected in to the exhaust system to remove harmful gasses from the engine exhaust.

Urea is made up of carbon, nitrogen and oxygen. It is found in urine.

Ad Blue system – machines have 2 tanks one ad blue and one fuel – generally ad blue usage is 5-7% of fuel usage.

All machines have a standard filter design – DO NOT tamper

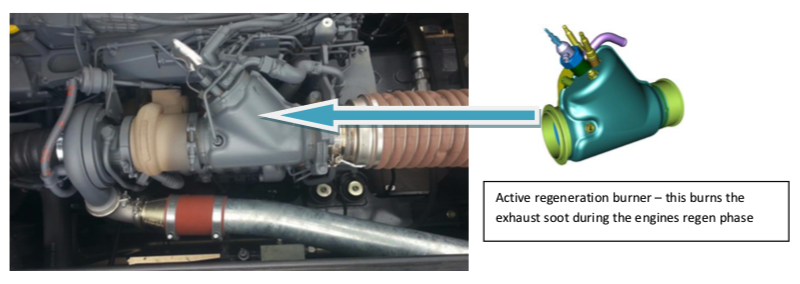

4. Regen System (EGR)

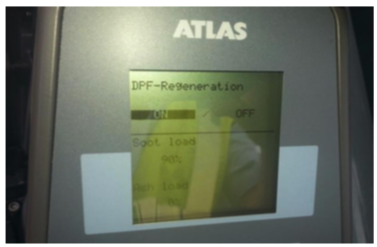

Regen – the system relies on the diesel particle filter sorting the “bad” exhaust gasses (soot) then when fuel us burnt off using a high temperature flame. The engine will notify the operator that the system needs to regenerate via the gab display.

Actve regeneration burner – this burns the exhaust soot during the engines regen phase

NOTE: the above is a guideline only, depending on the manufacturer, a combination of DOC, SCR and EGR can be used and also different systems within each of these options is available – always refer to the operator manual specific to the machine you are operating.

DO’s and DONT’s – the most important part to note!

AD BLUE

- ONLY ad blue must be used in the system

- CIRITCAL – use clean containers only, preferrably ad blue containers with self contained nozzles to reduce cross contamination. NOTE: ANY contamination – dirt/oil/fuel will damage the system – and are costly to repair!

- Clean area around the cap to prevent any dirt/ debris falling into the tank

- Ad blue must not be diluted with water

- Do not tamper with the ad blue cap/ filler nozzle

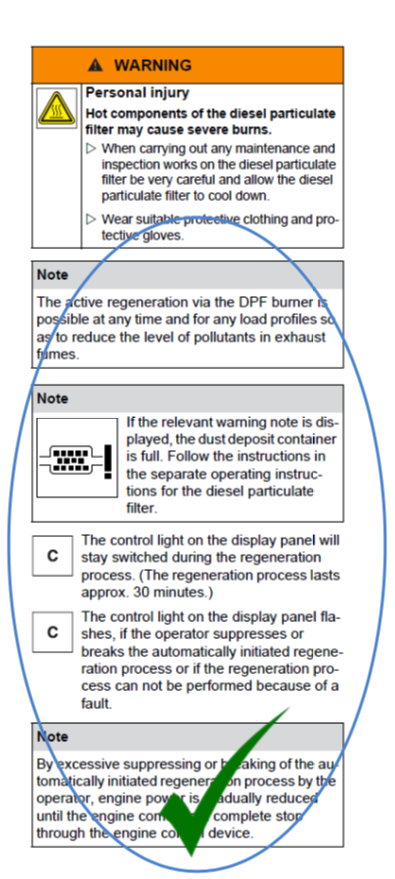

REGEN

- When machine shows a regen is required – allow this to complete! Follow the manufacturer’s instructions in the operators manual – if ignored, depending on the system, it could shut down after a pre-determined number of attempts – dealer call out then required

Read the operators manual – become familiar with the system – all machine are different on how they advise operators where the system is at during the regen cycle

Fuel – Important changes to the specification of fuel required

Another very important note is that the fuel quality is also very important – for new engine designs the fuel MUST be low sulphur content to EN590 standard, maximum of 10ppm (parts per million) otherwise it will simply block up the catalytic convertor and reduce other engine components life.

Poor fuel will cause expensive component failures

Did you know ? – the correct engine specification of oil MUST be used – refer to operator manual – important to the life of engine components.

Engine technology is rapidly changing, take note of these changes as failure to do so will lead to costly unnecessary repairs to the engine systems – which might not be covered under warranty!

In most cases, failure to adhere to the operator’s instruction manual, for the fuel or after treatment system could put the machine into torque reduction or limp mode!

What happens when the instructions are not followed ?

Ad blue/ SCR system

Q: What happens when contamination occurs ?

A: When incorrect fluid is entered into the Ad Blue system it will fail

Urea tank filter – evidence of soil/ sand in tank (not using clean containers to fill and/ or not cleaning tank filler area when topping up

As above this time filled with incorrect fluid

Litmus test proves contamination

When contamination occurs the system must be removed and thouroughly cleaned out, tank, pipes and filters. In most cases the pump usually becomes damaged and needs to be replaced.

Q: What happens when incorrect fuel is used (high sulphur) ?

Cross section of SCR catalytic convertor 70% blocked due to incorrect fuel being used – high idling can also contribute towards a blocked cat

Did you know…

Working with Terex Trucks, a “sealed” ad blue system has been developed to help keep contaminants out of the system, available as an optional extra, Ad Blue is pumped from a clean container into tank via a filter system.

Leave A Comment

You must be logged in to post a comment.